Products

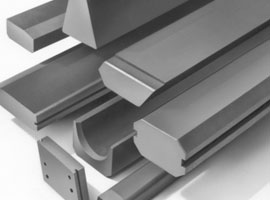

EXTRUSION TOOLS

Extrusion Press components & ToolingWe are leading providers of cost effective solutions and high precision integrated extrusion solutions for the extrusion tools precision extrusion tool manufacturing is rocket science and we over the years have perfected this art.

We provide technical consultancy effective services to our customers in the aluminium extrusion industry, we work closely with the extruder to understand the performance parameters to ensure that they get the best life and performance our of the tools and we carefully monitor the other functions that affect the life and performance of the extrusion tools.

ASCONA GmbH

Measuring systems for aluminium profilesASCONA is the leading specialist for software and solutions in optical profile measuring technology. ASCONA offers measuring systems which are tailor made for customers, including consultancy and a calculable increase in production efficiency through innovative technology.

More than 200 system installations in the aluminium, plastics, rubber, metal and electronics sector are convincing proof of our competence.

We have set the focus of our activities on optical profile measuring technology and this is why we have accumulated a unique know-how in this speciality sector.

Telon Yida

HIGH TEMPERATURE ROLLERS & BELTSTELON YIDA, with her rapid development, in a short time of ten years, have laid a good foundation for today’s brand TELON and CASTONG by consistent pursuing for innovation and quality.

There are three factories under TELON YIDA group, and three brand, TELON, CASTON, WANTAI, with products cover more than ten fields such as aluminum extrusion, glass, automobile, smelting, casting, PPE, household articles, etc.

TELON YIDA is the first one in the industry that acquired ISO9000 certificate, and quite a lot of her products with CE certificate. Especially for heat resistant protective products, the quality standard is even higher than that of CE required.

Graphite COVA

Graphite electrodes, coating for graphite electrodes and special carbon and graphite productsGraphite Cova is a supplier of graphite electrodes, coating for graphite electrodes and special carbon and graphite products. Throughout the world, Graphite COVA is the only producer and supplier of protective coating for graphite electrodes. This sophisticated product gives excellent antioxidation properties to graphite electrodes and reduces the specific consumption of graphite considerably. Coated electrodes are used for the production of electric steel as well as for manufacturing non-metallic products in electric arc procesing.

The protective coating consists of several layers and is added to the electrode surface in a complicated, multilevel production process. A special characteristic of the coating technology is the electric arc treatment of every single layer. The latest patent dates from the year 2000.

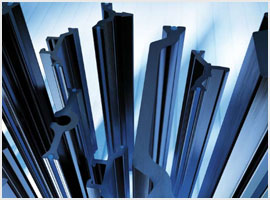

Insulbar

POLYAMIDE THERMAL BREAK STRIPS & PROFILESWe coordinate developments for specific applications worldwide, yet service our customers on a local basis. Continuous global exchanges enable us to learn and benefit from each other, even if regional and cultural differences continue to exist. As a customer, you too can benefit from this invaluable experience as much as the company itself.

Our versatility, however, lies not only in our global activi- ties but also our broad product spectrum. Thanks to numerous process engineering technologies and materi- als, we are able to accompany our customers' projects from the raw material to the actual application stage.

FIZETA

producing carbide tipped circular saw blades in all diametersFizeta is producing carbide tipped circular saw blades in all diameters and number of teeth which are used today in the production and processing of Aluminium. Fizeta is producing carbide tipped circular saw blades in all diameters and number of teeth which are used today in the production and processing of Aluminium.

Fizeta cutting tool manufacturing process meets customers needs and safety norms. Fizeta is producing carbide tipped circular saw blades in all diameters and number of teeth which are used today in the production and processing of Aluminium.

Akkurt

aluminium Profıle Polishıng MachıneTwo group of polishing brushes, each 1.000 mm length and driven 37 Kw Electrical Motor. You can use brush diameter up to 500 mm. You can set all brushes on the 80 mm diameter brush spindle in the workshop. Set up in to machine is very easy and fast because of counter sliding bed. Brush rotating speed can be adjusted from 0 up to 2000 with equipment inverter system.

Each brush group precisely moving on separate vertically located 8 linear bearing through hydraulic cylinders. Brush groups have separate hydraulic cylinder system for fast upward and downward movement on the Aluminium Due to this system, operator do not make any adjustment for each start and also this system eliminate time loosing and saving time.

This system also giving extraordinary working possibility for thin extrusion profile which eliminate brush contact to the working table. The hydraulic system power unit is total 1,5 Kw (2 Hp)